Pad Printing Applications

Liberty Clark provides pad printing and screen printing services. We offer state-of-the-art commercial equipment to decorate three dimensional surfaces. We have accumulated a sizable database of suitable ink systems for various substrates which provides durable ink adhesion. As ink-subject matter experts, the team at Liberty Clark will help guide you to choose the most appropriate ink system for your substrate. Our substrate decorating experience includes:

Pad Printing On Plastics:

- Nylon 6/6, Nylon 11, Nylon 12

- Homopolymer and Copolymer

- ABS

- MABS

- Acrylic

- Copolyster

- Polycarbonate

- PC-ABS

- Polyethylene

- Polypropylene

- Polyetherimide

- PVC

- Polyurethane

- Polyarylamide

- Thermoplastic Elastomer

Other Material:

- Screen Printing On Powder Coated Metal

- Pad Printing On Glass

- Pad Printing On Ceramic

- Pad Printing On Silicone

- Screen Printing On Plastic

- And Many Other Substrates

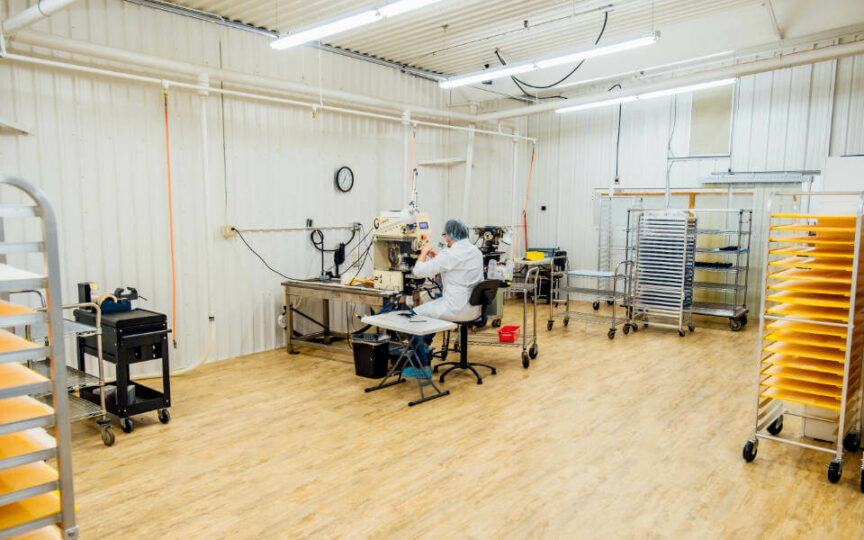

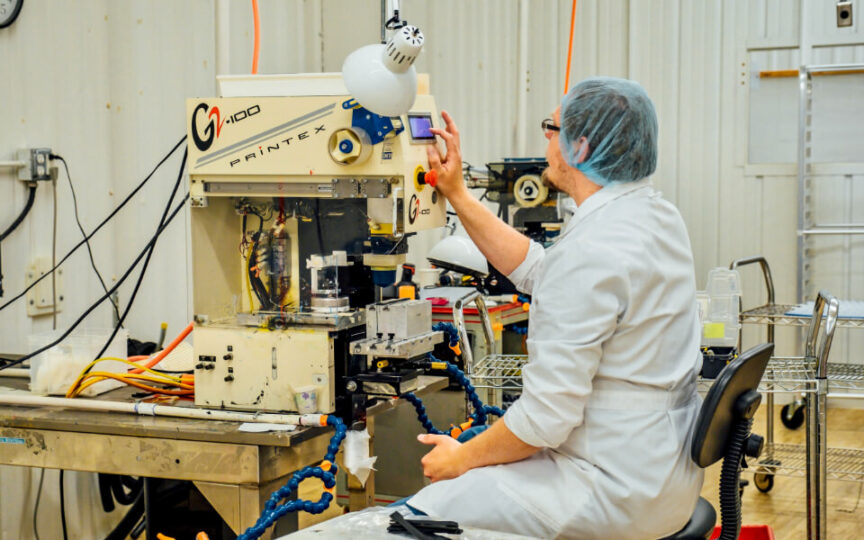

Class 7 Cleanroom Printing

Our facility has a 1,000 square foot Class-7 certified clean room for pad printing operations. This dedicated room has a very low level of environmental contaminant particles such as dust, airborne microbes, aerosol particles, and chemical vapors. More accurately, our clean room has a controlled level of contamination that is specified by the number of particles per cubic meter at a specified particle size. This controlled environment is used primarily for medical device pad printing.

The air entering our clean room is filtered and continuously recirculated through High-Efficiency Particulate Air (HEPA) filters to remove external and internal generated contaminants. Staff enter this room through a preparatory area wearing hair nets, powder-free nitrile gloves, booties, and lab coats. Equipment inside this room is designed to generate minimal air contamination. Even the printing presses are designed to generate minimum amounts of airborne contaminants. Syringe barrel pad printing is a common application for Class 7 cleanroom operations.

High Precision Pad Printing Services

At Liberty Clark, our high precision pad printing services meet the rigorous ISO standards of both medical and industrial applications. Our facility is equipped with cutting-edge technology that ensures consistent and accurate printing on a variety of substrates. Whether working with complex geometries or designs, our skilled team is adept at delivering precise and repeatable results. We take pride in our attention to detail, ensuring that every product we print meets the highest quality standards. With our advanced pad printing capabilities, we provide reliable solutions tailored to your specific needs, ensuring superior adhesion and durability of the printed images. Our commitment to excellence guarantees that your products not only look great but also perform exceptionally in their intended applications.

Looking for a printing quote?

Contact us today for a quote on your next printing project.